This enables data-driven decision-making, continuous process improvement, and strategic planning for future growth. Manufacturers can derive insights regarding demand patterns, production efficiency, and inventory performance. Inventory management systems offer comprehensive analytics and reporting. This fosters customer loyalty and positive brand experiences. Also, fewer stockouts and better order fulfillment enhance customer satisfaction. This translates to increased productivity and faster time-to-market.Īccurate inventory control ensures the production of fresh and high-quality products for customers. Manufacturers can optimize production cycles, reduce downtime, and allocate resources more effectively. Streamlining aspects of inventory management, such as automated tracking, accurate forecasting, and timely replenishment, enhance operational efficiency. Additionally, efficient expiration management reduces waste due to spoilage or obsolescence. Optimizing inventory levels and preventing excessive stock items from entering the production process naturally reduces waste and operational costs. Real-time monitoring of quality parameters and expiration dates reduces the risk of compromised products reaching consumers. Manufacturers can enforce stringent quality control measures, ensuring the consistency, safety, and integrity of their products. Benefits of inventory control systems in food and beverage manufacturing This ensures compliance and helps mitigate the risk of penalties. Inventory control system s offer features that assist in meeting regulatory obligations around labeling, and traceability. Food and beverage manufacturers can accurately track stock, anticipate shortages or excesses, and make informed decisions about production and procurement. By maintaining strict quality standards, food and beverage manufacturers can consistently deliver products that meet customer expectations and comply with regulatory requirements.Īdvanced inventory control system s provide real-time visibility into inventory levels, locations, and movement. This prevents them from using expired items, while helping reduce waste and maintaining product freshness and quality.īe it establishing benchmarks for quality, monitoring production processes, or conducting quality checks at various stages, inventory control system s can be used to aid such endeavors. Inventory control system s for food manufacturers enable them to track the expiration dates of ingredients, raw materials, finished products, and more. In the event of quality issues or product recalls, precise lot and batch tracking facilitate swift identification and targeted responses.

Fishbowl inventory management software full#

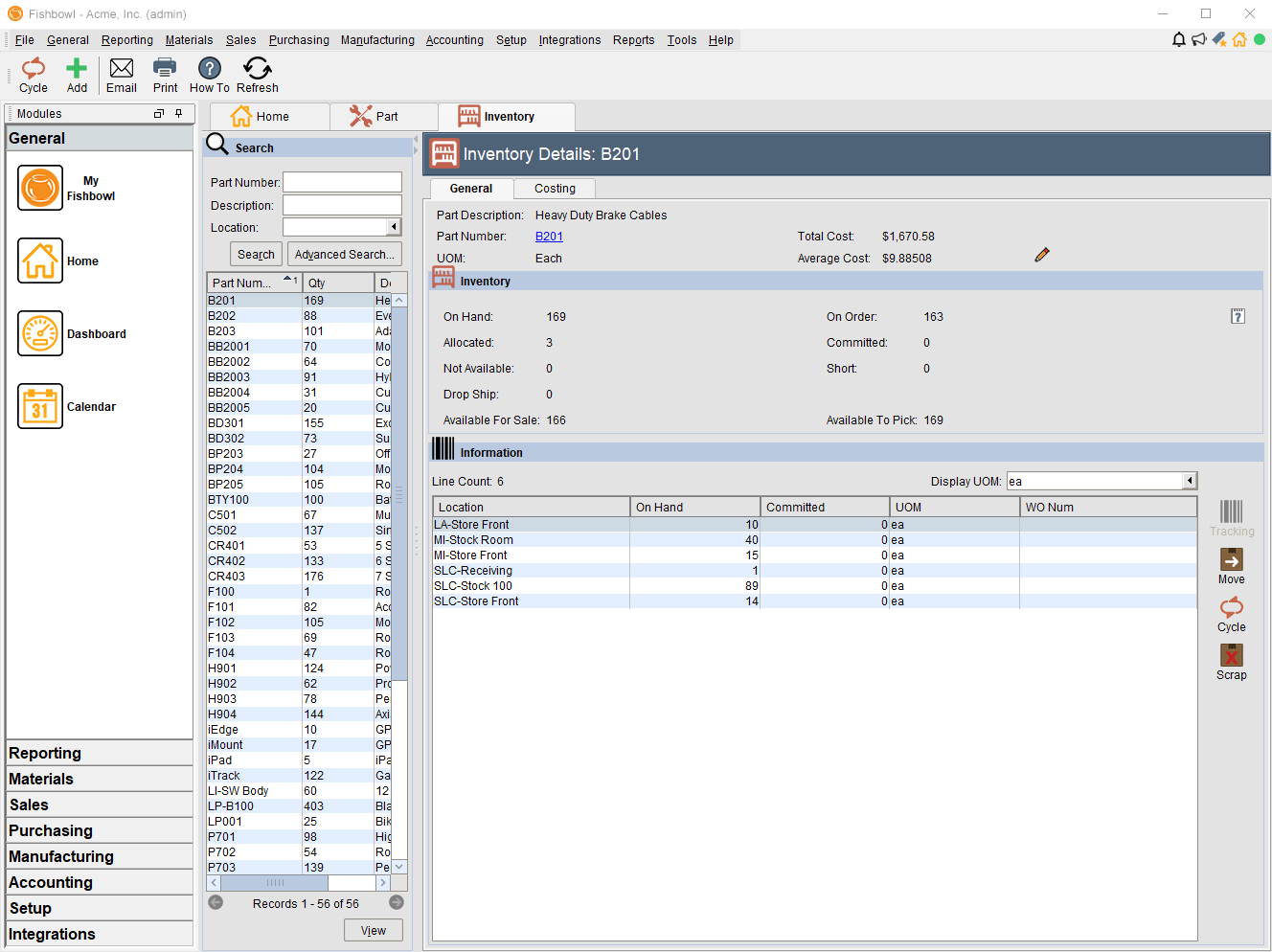

This allows manufacturers to trace ingredients and finished products throughout the production process, ensuring full visibility and accountability. Key features of food and beverage inventory control softwareįor manufacturers in the food and beverage industry, inventory control system s provide robust lot and batch tracking capabilities.

Let’s look at the key features and benefits of inventory control system s in food and beverage manufacturing. To this end, a robust inventory control management system is a must so that food and beverage manufacturers can meet their targets while maintaining regulatory compliance. Keeping close tabs on these activities helps facilitate profitability, as organizations strive to meet the ever-growing demands of consumers.

In addition to other aspects of operations, F&B companies must manage raw materials, track production processes, and ensure the timely delivery of finished products. The ability to uphold stringent quality standards, while managing inventory expiration dates is challenging, to say the least. In the fast-paced market of food and beverage (F&B) manufacturing, maintaining precise control over inventory is paramount to success.

0 kommentar(er)

0 kommentar(er)